To enable the transport of electricity from point A to point B, an effective connection between cables and devices is required. A sustainable and qualitative mechanical link will ensure an excellent electrical connection. This connection is ensured by direct contact of conductive metals. If the electrical connection is not done properly, a heating can occur and will lead to burning.

So, ensuring an optimal contact is a necessity. The mechanical tightening and the crimping are two methods which guarantee a mechanical connection between two elements.

Mechanical tightening, a flexible solution on the field

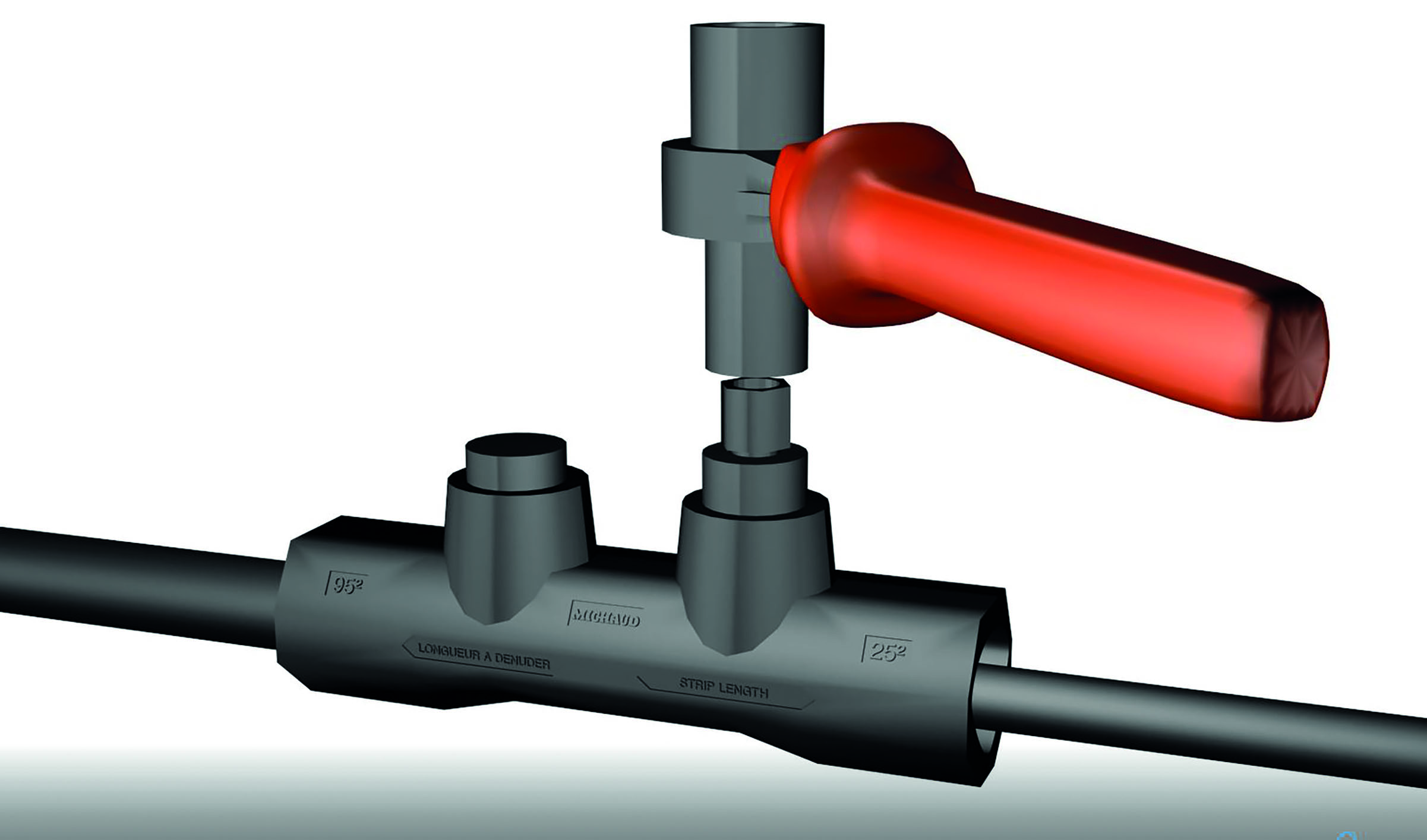

Regularly used on networks, the mechanical tightening consists on using one or several screws to create a connection terminal / conductor.

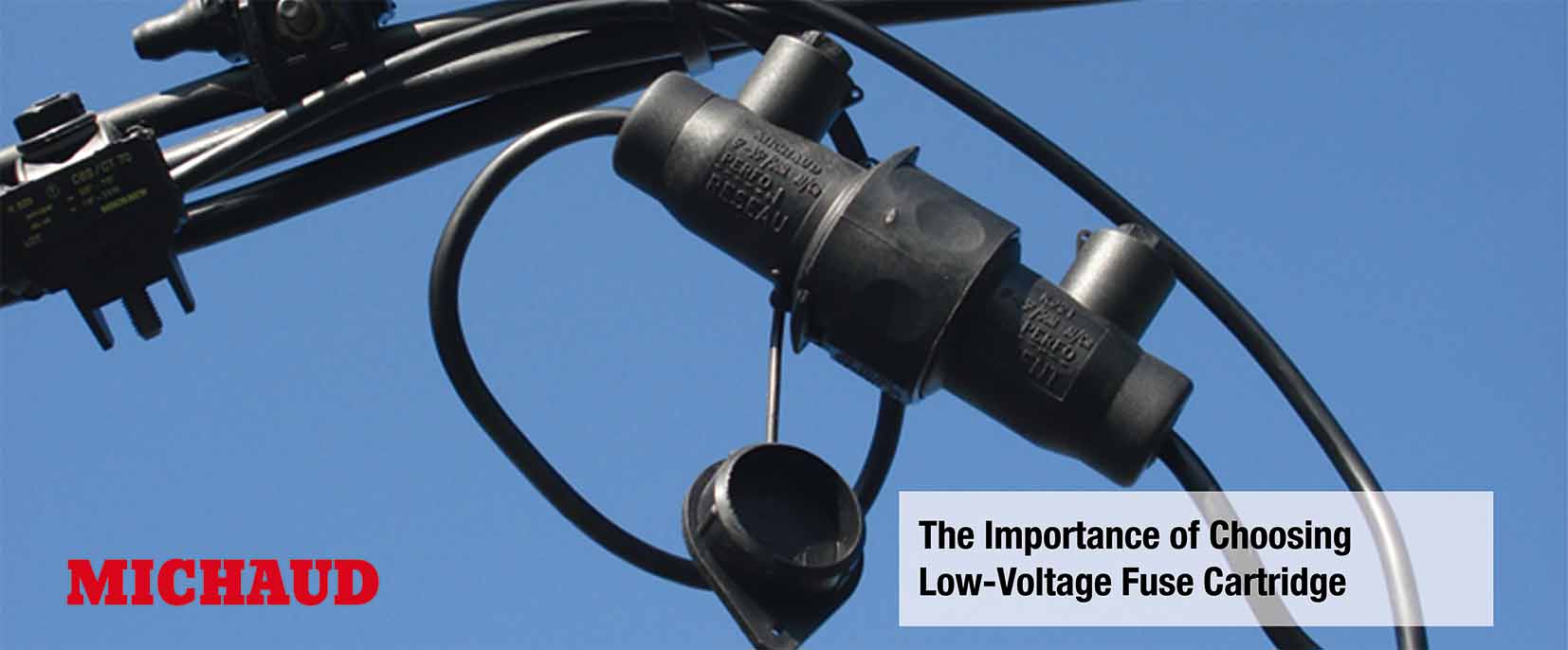

On low voltage networks, 2 types of technologies are operated : insulation piercing or stripping. With the first technique, the tightening helps to pierce the insulation by means of teeth which then catch the conductor as well. With a stripping connection, cable gets in contact with blades through the action of tightening.

+ The benefits of mechanical tightening

A tightening with screw is removable and offers the benefit to disconnect the conductor and reconnect it when this one was connected by means of stripping technology.

The mechanical tightening process offer easiness in the implementation. Thanks to it, the same product can receive a wide range of conductors cross section giving the fitter a flexibility on the field.

To ensure an optimal tightening (neither extreme neither poor) it is needed to tighten to the required torque. To guarantee this work, tools can be used like torque wrench. Other devices integrated on the screw help the fitter to ensure a good installation, we think of shear head screw. The screw head breaks when the required torque has been reached. If a strong connection is guaranteed, it leads to a good electrical connection as well.

The screw head can be equipped with a colored indicator enabling to control visually from the ground the right implementation of the product. If this is indicator is missing, that means that the head has broken properly and the tightening torque is respected.

The crimping, an non dismountable and sustainable solution

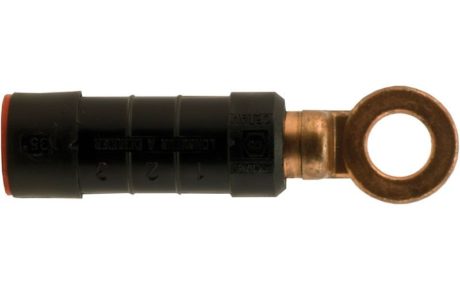

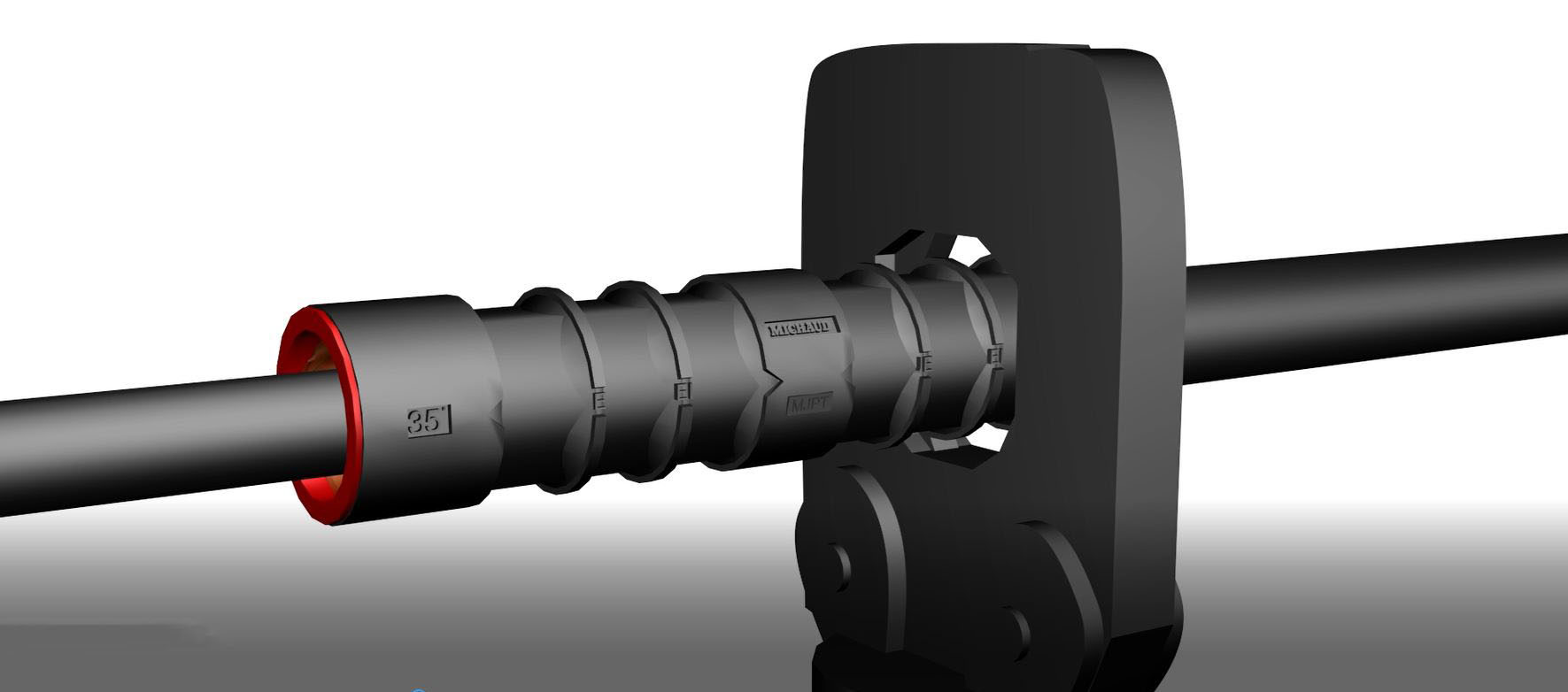

The crimping process is a way to tighten by material distortion. Mainly used to install sleeves or lugs, the crimping tool will apply a certain strength which will crush the product barrel against the bare conductor and enable a good connection between metals.

+ The benefits of compression

The crimping guarantees a non-dismountable connection within the years and enables its use under mechanical load.

To provide an optimum installation with this type of tightening, each terminal can only receive one conductor’s section in order to guarantee no gap or no empty space during crimping process. It means that you need a wide range of products code to match all the fields applications.

How to choose between two processes which guarantee the electrical connection ?

Each process will be more accurate one or another application : connection / disconnection ?, use under mechanical load ?, need to pierce the conductor insulation ?

Toolings is also a key parameter in choosing the process. For mechanical tightening, standard tools can be used like hexagonal wrench. For compression, a crimping tool and several dies are needed. It is an expensive tool, working with battery, and which brings some constraints when it comes to maintenance. It is easier for field teams to install products by means of screwing (when the device does not need an application under load).

To give options to its customers, MICHAUD offers connection, junction and ending fittings with mechanical of compression tightening.

And so, to operate a junction between two overhead cables, a compression sleeve will be more appropriate. On the contrary, in case of a sub-surface connection between underground and overhead cables alsongside the pole, a mechanical tightening sleeve seams a better option for the flexibility to cover several types of cables.

The two options in tightening are also possible for preinsulated lugs. The choice between mechanical tightening lugs or compression ones will depend on the mentioned topics above (flexibility to cover several cables section, tools…).

For the other devices screwing remains mainly used because of the easiness provided.