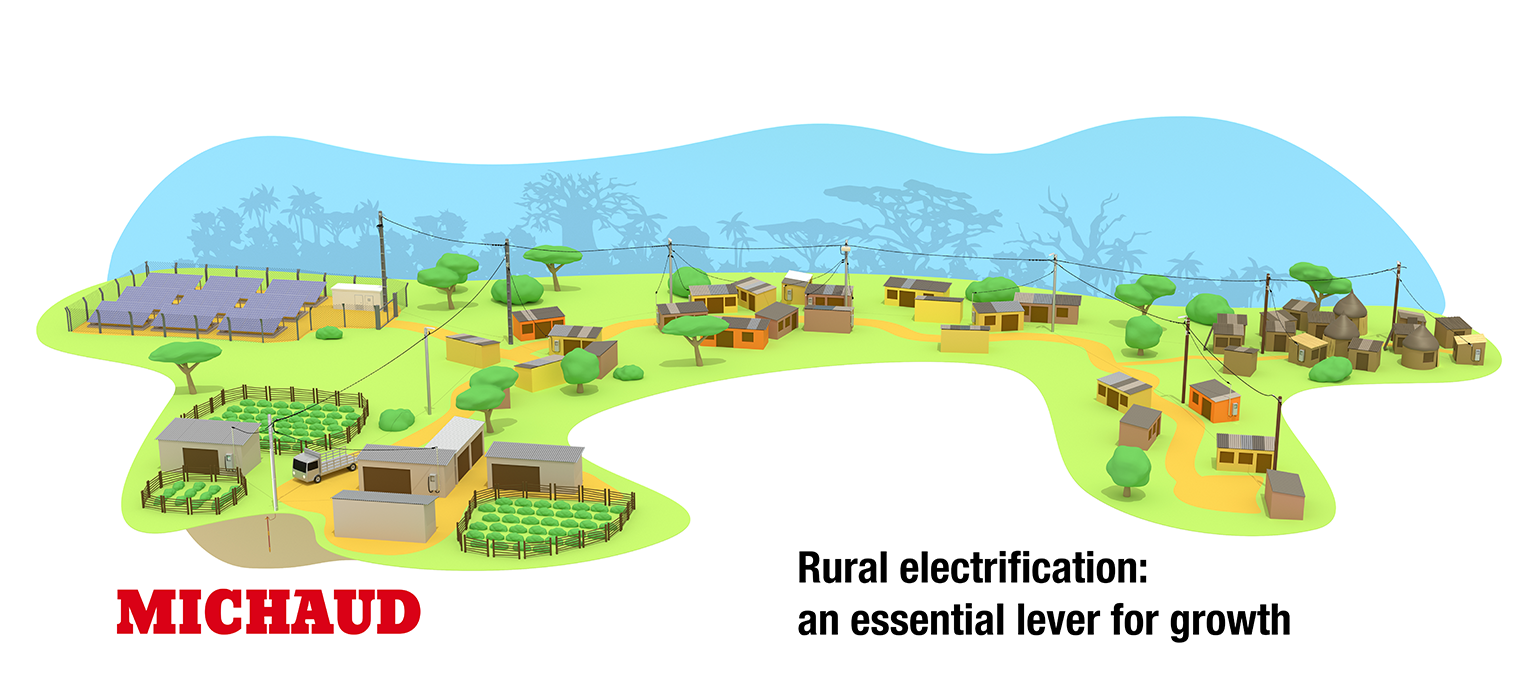

Composed of 80% overhead lines and 20% underground lines, the low-voltage electricity grid is used to distribute electricity to the house. The power lines used to connect subscribers to the network can be made of copper or aluminum. The shapes and characteristics of the conductors vary according to the applicable standards: round, sectoral, cable, multistrand, solid… All this information must be taken into consideration when connecting the network to the box in the home. In addition, the nature of the cable influences the installation.

Connecting the premise to the grid

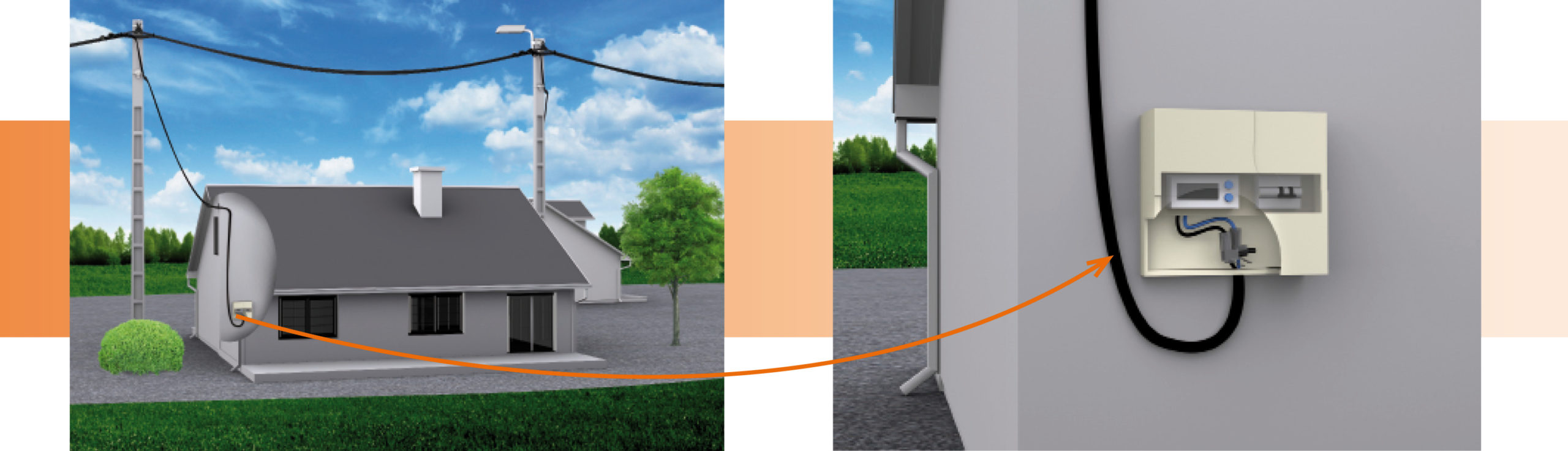

The house is therefore connected to the grid via a meter and protections that differ from country to country. The electrical cabinet that groups these elements is commonly referred to as a meter box. The dimensions of the latter vary according to the elements that compose it.

In general, the size of this box remains small and is likely to decrease further in the coming years due to ever smaller, more profitable and efficient emerging technologies. For the consumer, the small size of the electrical panel is a rather positive aspect, but this can make it difficult to install or maintain the connections between the network cables and the electrical panel.

There are three emerging issues with the connection of the network to the subscriber:

- Electrical panels are narrow but must accommodate quite a few connections,

- Ensure the transition between the aluminum service cable and the equipment’s terminals made of brass or copper,

- The conductors sections used in the house are not of the same order as for the network, but the connection must be made in complete safety and efficiency.

EBCP fittings have been developed to meet these constraints.

What is an EBCP?

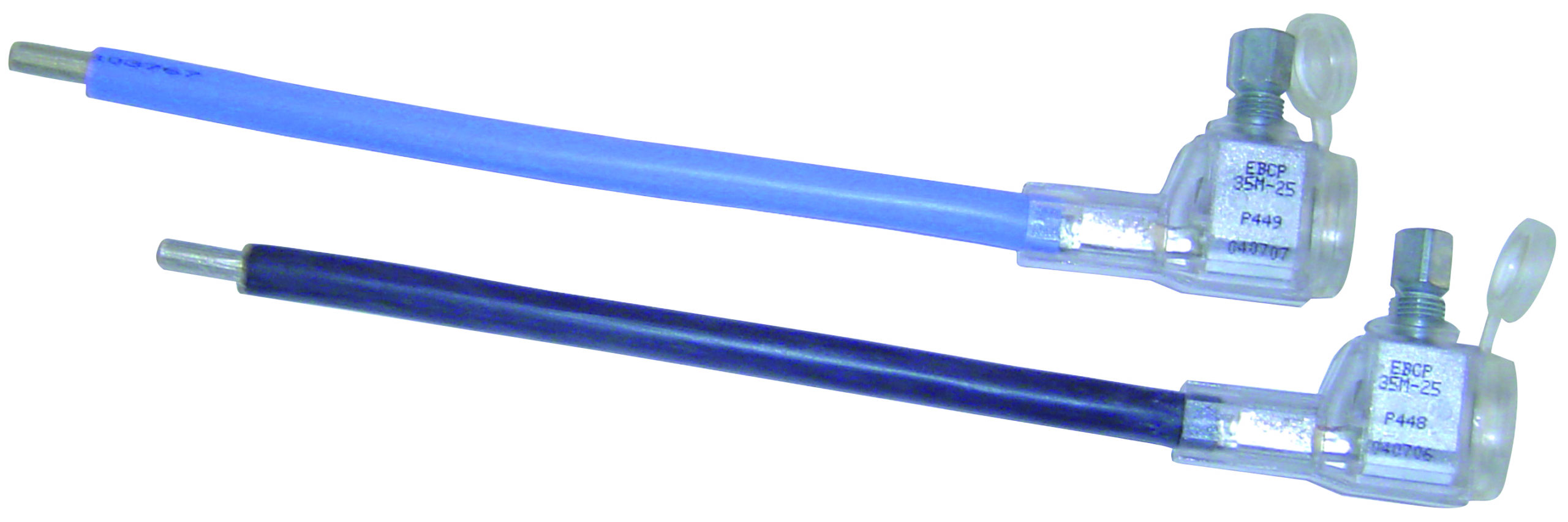

The abbreviation EBCP is used to refer to an Insulation Piercing End Connector. This product is related to a end with a tail. It is the physical combination of two products: a connector and a flexible cable. Its three main functions are the sections reduction, the tail flexibility and the aluminum/copper transition.

Used to safely connect the network with the equipment in the board of type: general circuit-breaker, circuit-breakers and cutouts or meters, it is a relevant element for connecting subscribers.

The implementation is realized in two steps:

- Connection of the connector to the network,

- Connection of the flexible cable to the desired equipment.

How to choose it?

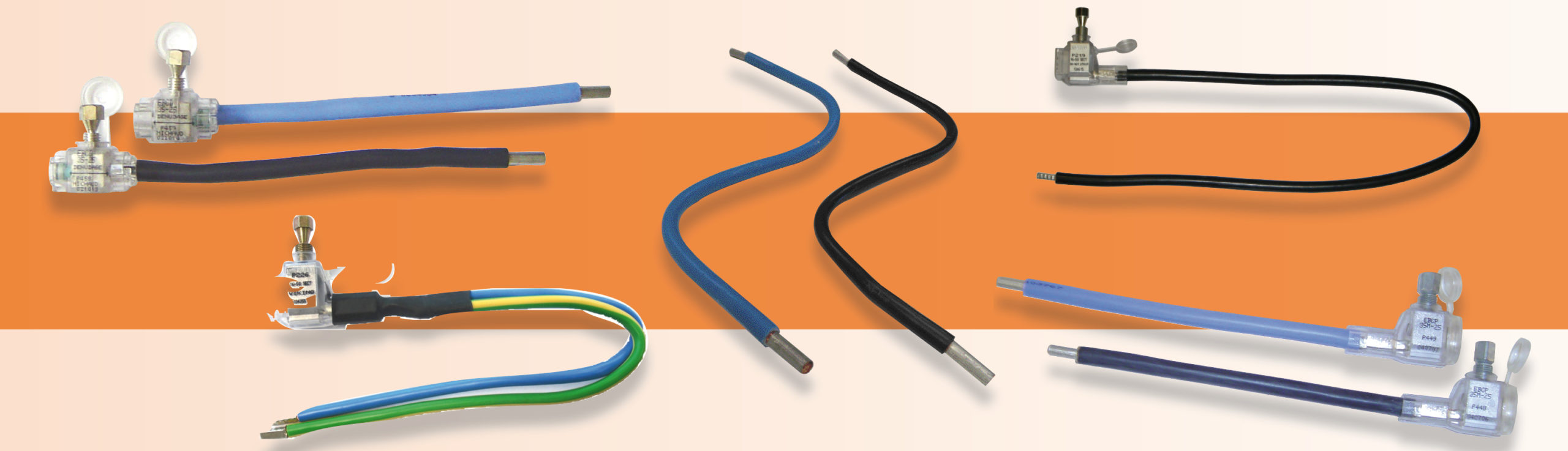

While the use of this product has been summarized above and demonstrates a unique solution which comprises a cable and a connector, there are variants and options which depend on the desired end use and network constraints. That’s why manufacturers offer different types of EBCP to meet market expectations.

– Adapt the technology to installation on the field

Depending on the country of destination of these products, it is not systematically expected of the screws. While it is customary for some to use metal heads or plastic ones, others prefer to ensure a proper use of the products using shear head screws. All these possible screw models can be found on the EBCP enabling to adapt to the final destination.

A variant of EBCP is also possible regarding to the nature of the connection. By definition EBCPs use the insulation-piercing technology which makes it easier to connect the cable without the need to remove the insulation. To adapt to installation habits, there is also a version of stripping end connectors (EBCD).

– Amperage: align with end-user consumption

The industrial customer will not consume the same amount of energy as the individual and therefore will not require the same power at the terminals of the device. Thus, each category of user will have its own intensity limit, due to power/intensity proportionality.

In order not to cause any electrical problems, it is important to adapt the EBCP tail’s section to the service cable one for a safe use.

– Capacities: choose the appropriate sections according to needs

For the connector part, the choice of capacities depends on the section of the service cable to be received. Generally, this type of cable is between 6 and 50mm².

For the subscriber connection part, the choice of the tail section depends on the equipment to be connected; it varies from 10 to 25mm² depending on the applied standards.

In general, we use to choose the first section of copper lower than the aluminium one. For example, if the connection cable is made of aluminium section 25mm² it will be recommended to use an EBCP with a tail in copper of section 16mm².

– Color: to facilitate the identification of conductors

Phase and neutral cables are very often of different colours in domestic installations. This is the case in most countries and it makes it possible to secure the intervention teams (installation or maintenance). Indeed, by identifying the phases and the neutral, it is more obvious for the fitters to ensure their safety. Thus, in France, there will be particularly blue or black EBCPs.

Other universal color codes such as yellow and green tails will also be used to distinguish the ground conductor.

– Complete systems

To facilitate field installation, manufacturers have adapted the packaging of the end connectors to offer systems in “kits”. This kind of solution refers to a set of EBCPs, generally 2 or 4, allowing the installer to find the neutral and the phase(s) in the same pack, respectively for single-phase or three-phases connections. This type of solution also presents a logistical interest by rationalizing orders and reducing its ecological impact.

– Respond to specific field issues

The problem of non-technical losses affects a number of countries around the world, particularly in emerging countries. Anti-fraud technology has therefore emerged to prevent the theft of electricity. By choosing EBCPs with a non-dismountable shear head, utilities can secure the connection and protect themselves from possible fraudulent manipulation. This technology also allows the installer to tighten the conductor to the required torque without specific tools and thus enable good electrical efficiency.