The low voltage network designed for electricity distribution implies to realize tap connections and junctions. These operations require to protect the conductor from external environment like meteorological phenomena, humidity or UV, to prevent:

- Lines disruption and increase of line losses

- Electrical risk for fitters and linemen

- Degradation of electrical connections quality

Hence, ensure equipment and electrical networks sealing is a priority for manufacturers and fitters. A shrinkable equipment can resolve these issues.

Two technologies coexist with the same vocation: create or recreate the weatherproof of an equipment ensuring a good electrical contact (watertightness and airtightness). These are heat-shrinkable and cold-shrinkable materials. Each one must be chosen according to specific situations and needs.

Product range

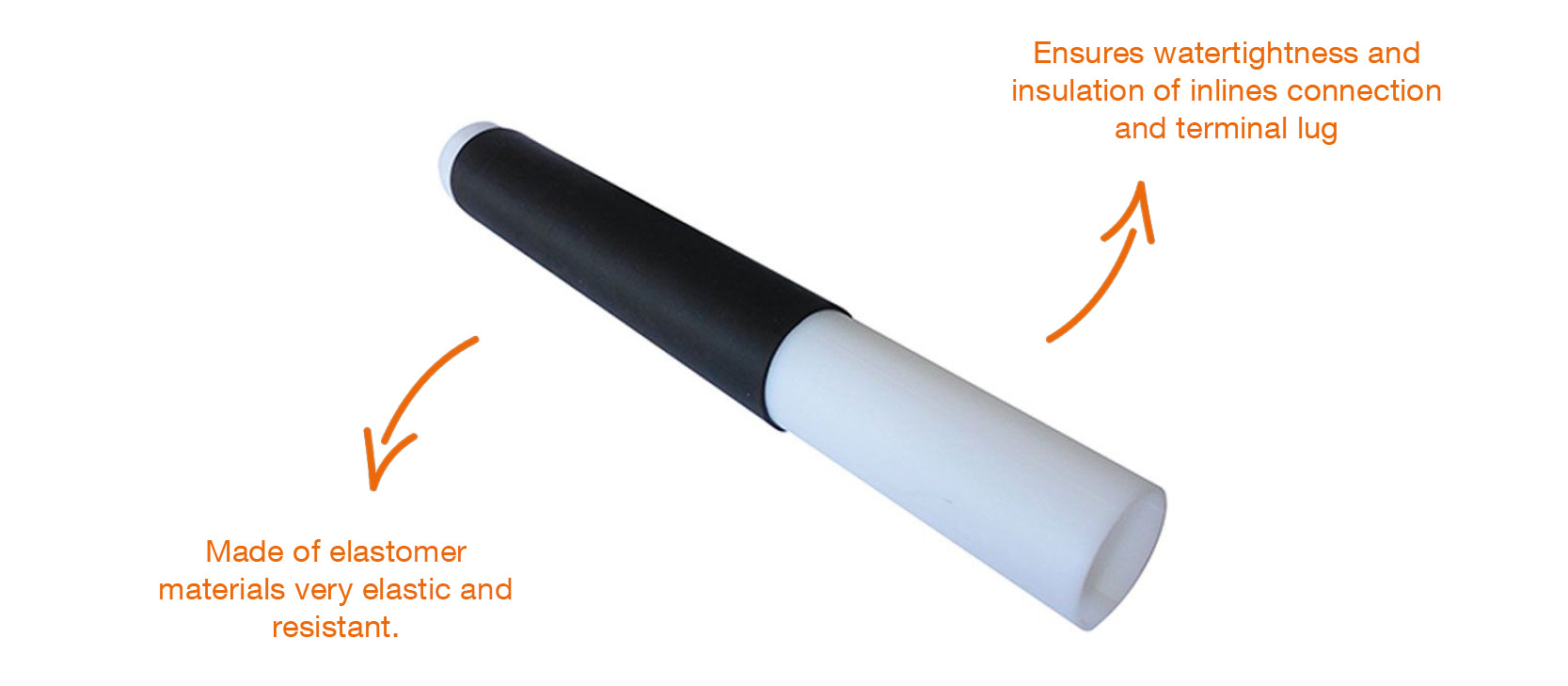

Tubing

We call them “sleeve” for small lengths and “sheath” for high ones. There are also split sleeves used especially for maintenance of overhead lines.

Cap

Also called “end cap”, it’s close-ended and provides physical protection and moisture sealing to cable end. Different caps are available to adjust to a wide range of sizes.

Breakout boots

It is used to separate cable’s conductor. If their functions still the same, their shape and conception material varies according to their implementation (cold or heat).

Two different technologies of shrinkable equipment

Heat shrinkable equipment

Thee heat shrinkable technology uses synthetic material that react to heat. So, when a high heat is applied on the product, this one will retract. This will allow it to fit the shape of equipment and ensure its watertightness.

To create an important source of heating to activate the shrinkage of the product, fitters need a special tool such as a blowtorch. In addition to the difficulty to lift it during an overhead operation it can be very dangerous if a gas line is nearby.

In this way, when the operation is highly sensitive for this type of technology, it is better to use a cold shrinkable equipment.

Cold shrinkable equipment

This technology made of synthetic materials. The product is prestretched with a removable rigid core, which, once removed, allows it to shrink into position forming a seal. It will compress around one or several equipment. The product fits perfectly to ensure the watertightness, insulate and protect.

Make the right choice

Each technology has benefits and disadvantages. While heat shrinkable technology remains competitive and offers many options regarding models and types, it can be difficult to implement during its installation.

The cold shrinkable equipmentis easier to install but more expensive and generate waste.

Heat shrinkable

| Benefits | Disadvantages |

|---|---|

| Competitive prices | Tools required |

| UV resistance | Fire risk |

| Many options | Specific know-how |

Cold shrinkable

| Benefits | Disadvantages |

|---|---|

| Easy to install | Generate waste |

| UV resistance | Reduced life time before installation |

| Quick operation |

Practical cases

Shrinkable equipment can be required for many uses. To help you to make your choice, find some examples of installation cases where this kind of equipment can be required.

Underground junctions

Electrical distribution network of big cities is often underground. Issues in terms of aestheticism but also to reduce space congestion are at the origin of the choice.

The area of this network is not very extended but we can observe many branching due to population density. Many connections and tap connections must be realized requiring accessories like connectors or sleeves which are implemented on the cable

In this case, it is necessary to use equipment which guarantees a perfect sealing like cold shrinkable equipment designed to adapt after shrinking to the shape of connection accessories.

Aerial-underground junctions

In extra-urban and rural areas raised another issues: distances to reach are longer and the network must adapt. That’s why, the network is made overhead lines. These lines get many advantages:

- Less expensive than underground ones

- The maintenance is easier to achieve

When both networks (underground and overhead) must be connected together, some specific junctions for connection of aerial-underground networks are required :

- 3 phase sleeves

- 1 neutral sleeve

- 4 heat shrinkable sheaths

- 1 cable breakout sealing with 4 ends

Thanks to these products, the junction is secured against water and dust infiltration.

Dry countries

Some countries have an arid and dry climate. It is important to take some precautions, which meant new issues for installation and maintenance of the electric grid.

Indeed, using a heat source can be very dangerous for fitters and the environment. The handling of blowtorch is prohibited on that kind of territories due to the increased risk of fire.

Therefore, a cold shrinkable equipment is preferred. .